10th semester // 18 weeks // individual project

MASTER'S THESIS

Designing an adjustable, affordable below-knee prosthesis that reduces the need of specialists and fabrication time, contributing to faster rehabilitation in crisis areas

Context

Armed conflicts, such as those in Ukraine and Gaza, have caused a sharp rise in the demand for prostheses, as many injuries result in amputations. Prosthetic sockets are custom-made; a process that is costly, time-consuming, and dependent on specialists with years of experience. As a result, it is nearly impossible to meet the urgent demand in crisis areas, with Ukraine alone having tens of thousands of amputees waiting for prostheses.

At the same time, more than 80% of people in need of prosthetics live in developing countries with little to no access to prostheses. The cost of traveling to the clinic and the recovery treatment is too expensive, as well as the prosthesis itself. With the average leg prosthesis costing around $10,000, and the average daily wage being only $2, it’s clear that the current market is far from meeting the needs of those who depend on it.

The product

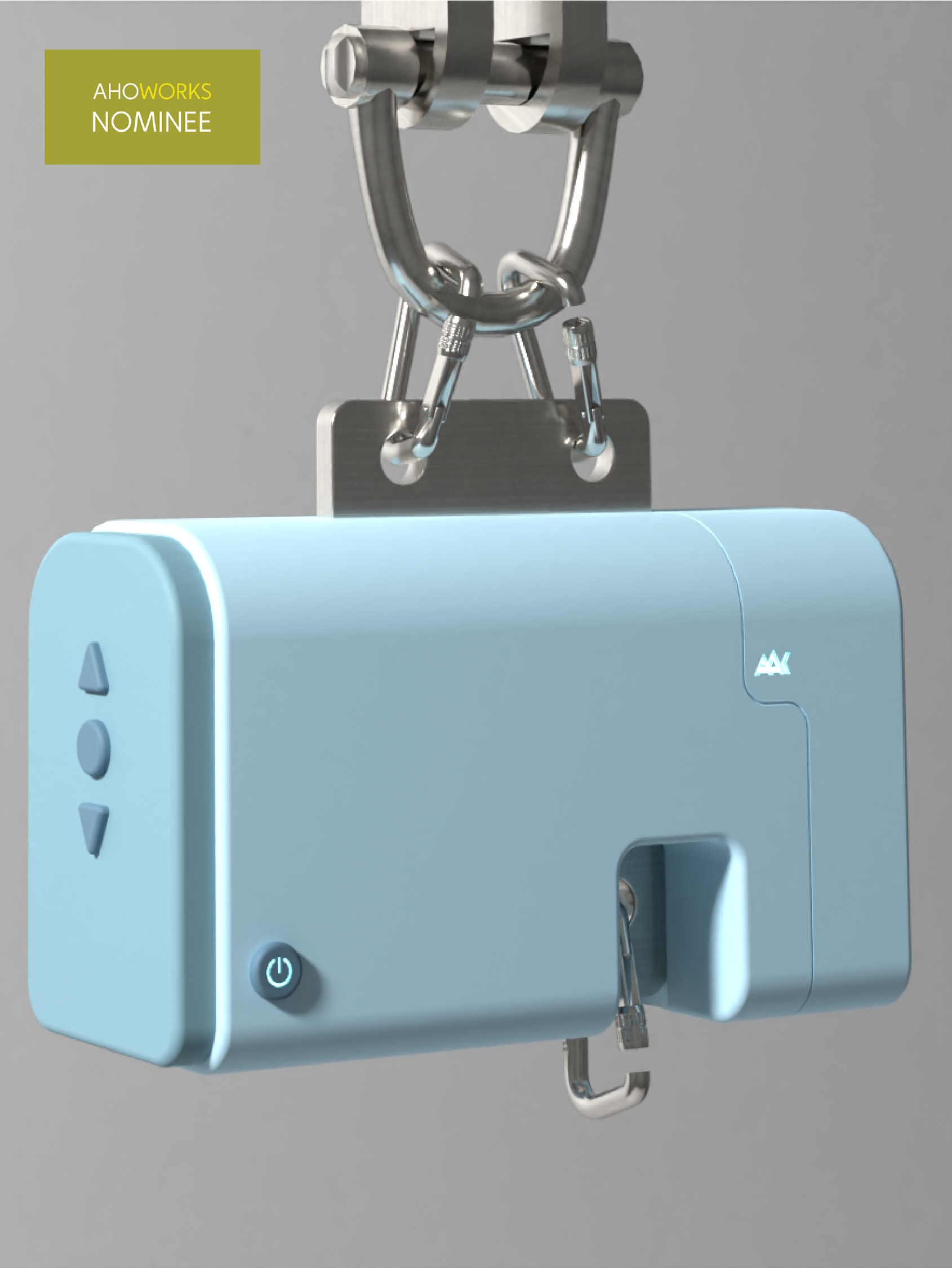

This lead to my master's thesis Urgent Prosthetics, exploring how prosthetics can go from being custom made to being mass produced. The result is a package of already made components that can be adjusted to fit different limb shapes.

The prosthesis is pre-made and ready to be distributed by humanitarian organizations. Orthopedists can now focus on fitting the prosthesis instead of production, saving several weeks of appointments. This also reduces the equipment needed to only an unbrako key, and makes it possible to train available healthcare staff.

The inflatable liner makes it possible to adjust to the right fit and comfort. It evens out the gap between the residual limb and prosthesis, and provides the needed compression.

The air can be adjusted throughout the day without taking off the prosthesis, contrary to today's solution with layers of socks.

The liner is made in two parts for optimized cleaning and repairing.

Both the liner and prosthesis is made to fit both right and left leg.

Holes in the bottom allows for a 1 cm adjustment in each direction.

Length adjustments in both the socket and pylon allows the prosthesis to fit different limb shapes.

Process

Desktop research, defining problem areas

Field research: Visit at Ortopediteknikk

Field research: visit at Sophies Minde

Amputated 1 year ago

Amputated 20 years ago

User interviews

Early ideation workshop

Workshop with users

Concept development

Consultations with orthopedists

Early prototyping

User testing

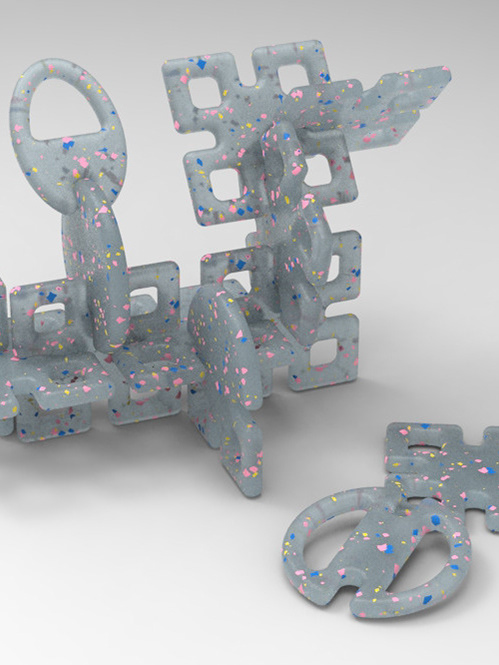

Prototyping: SLS & FDM print

Prototyping: preparation & spray painting